What are the scope and materials of auto paper bag making machine?

Applicable paper quality: kraft paper, coated paper, white paper, white cardboard (including laminated paper)

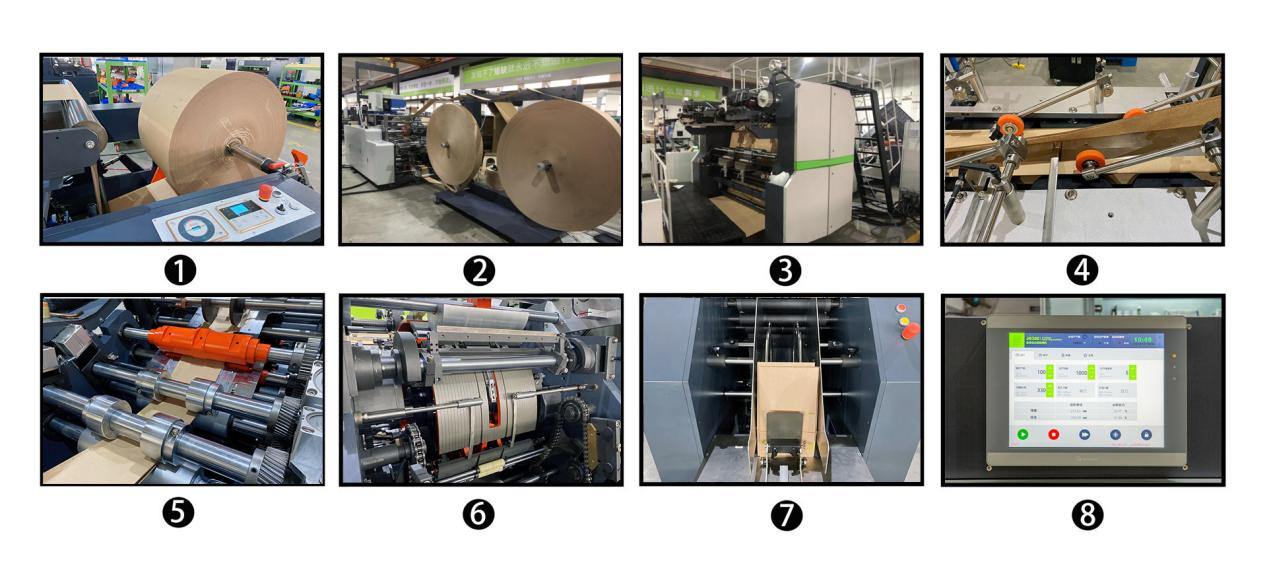

The auto paper bag making machine is to manually put the unsealed paper tube into the bottom card, and then go through the processes of automatic conveying, automatic glue spraying, automatic bottom sticking, automatic compaction, etc., and output it as a back-sealing paper bag. The machine is equipped with four spray guns, and customers can adjust the thickness of the glue and the position of the glue according to the requirements of the paper bag. Speed: 60-80 m/min

What is the practical value of an automatic paper bag manufacturing machine?

In manufacturing, there are numerous instances where different types of bags are required, and almost all of these bags need to have seamless seams. In industries such as chemicals, food, and building materials, where packaging is in high demand, it is common to utilize seam technology. These industries encompass all aspects of life, including food, clothing, shelter, and transportation. Almost every corner of our daily lives requires the convenient, efficient, durable, and aesthetically pleasing sewing technology provided by an automatic paper bag manufacturing machine.

What is the principle of using an automatic paper bag making machine?

This kind of sealing machine has a simple structure and basic principle, and it seals at a faster speed. Therefore, it is commonly used for sealing high pressure polyethylene film and polyethylene composite film. However, it is not suitable for sealing films that easily fold or dissolve when exposed to heat. It uses a single-pulse heat sealing method. For instance, the film made of nickel-chromium alloy strip is pressed onto the high-temperature plastic, and the nickel-chromium alloy strip is instantly heated by a large current, achieving the sealing process.