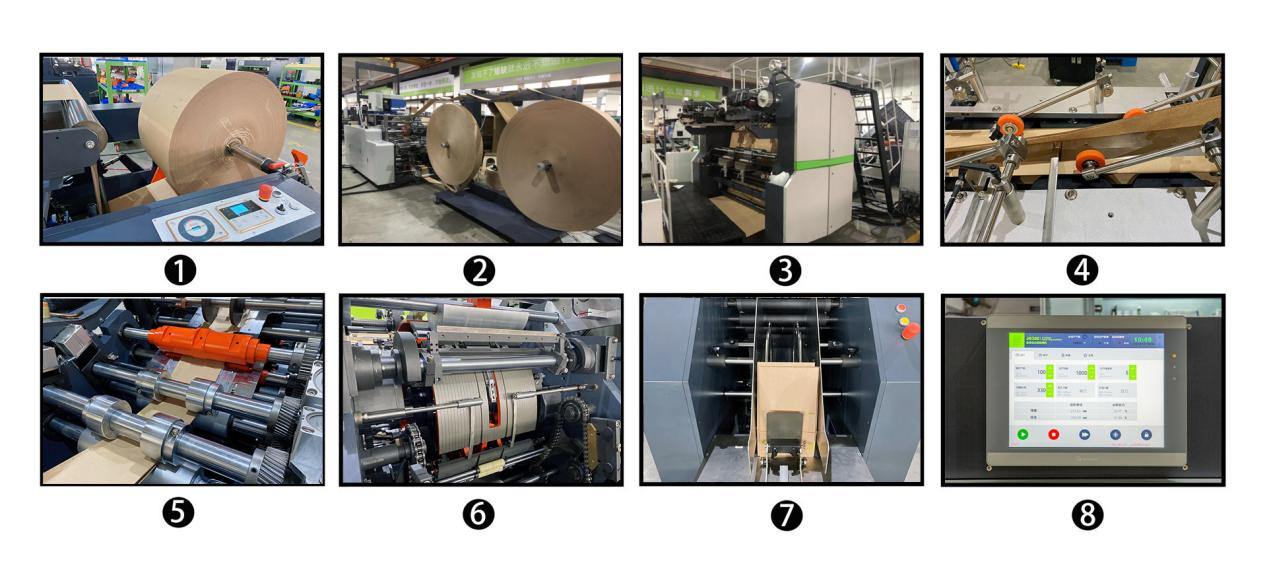

The RKFD-450 Square bottom paper bag machine is an advanced piece of equipment that is designed to produce high-quality paper bags with a square bottom. This unique design makes the bags more stable and sturdy, making them ideal for use in a wide range of applications such as retail, grocery stores, and food service industries. The machine is capable of producing up to 220 bags per minute, which makes it a highly efficient solution for businesses that need to produce large volumes of paper bags.

One of the key features of the RKFD-450 is its versatility. The machine can produce bags of various sizes, ranging from small bags suitable for carrying personal items to large bags that can hold multiple grocery items. This versatility makes the machine ideal for businesses that need to cater to a range of different products and customers.

Another significant feature of the RKFD-450 is its efficiency. The machine is designed to operate at high speed with minimal downtime, allowing businesses to increase their production rates and reduce their labor costs. The machine's automatic operation means that it can produce bags continuously without requiring human intervention, which further increases efficiency and reduces the chances of errors or defects.

The RKFD-450 is also very easy to operate, thanks to its user-friendly interface and intuitive control panel. This allows operators to quickly and easily set up and monitor the machine, even if they have no prior experience with similar equipment. The machine also comes with various safety features that help prevent accidents or injuries, making it a safe and reliable choice for any business.

In terms of durability, the RKFD-450 is built to last. The machine is constructed from high-quality materials, including a robust frame and premium components, which ensure that it can withstand the rigors of constant use. This makes it an excellent investment for businesses that are looking for long-term solutions for their paper bag manufacturing needs.

Overall, the RKFD-450 Square bottom paper bag machine is a highly efficient, versatile, and reliable piece of equipment that can help businesses improve their paper bag manufacturing capabilities. With its unique square bottom design, high production rates, easy operation, and durable construction, it is an excellent choice for any business that needs to produce high-quality paper bags for use in their daily operations.