Advanced High-Speed Square Bottom Paper Bag Machine for Mass Production

The RKFD-550 machine for square bottom paper bags is a cutting-edge and effective device engineered to manufacture top-notch square bottom paper bags. This machine operates fully automatically, ensuring a continuous production of paper bags without the requirement of frequent human involvement. As a result, it is an excellent choice for large-scale paper bag production.

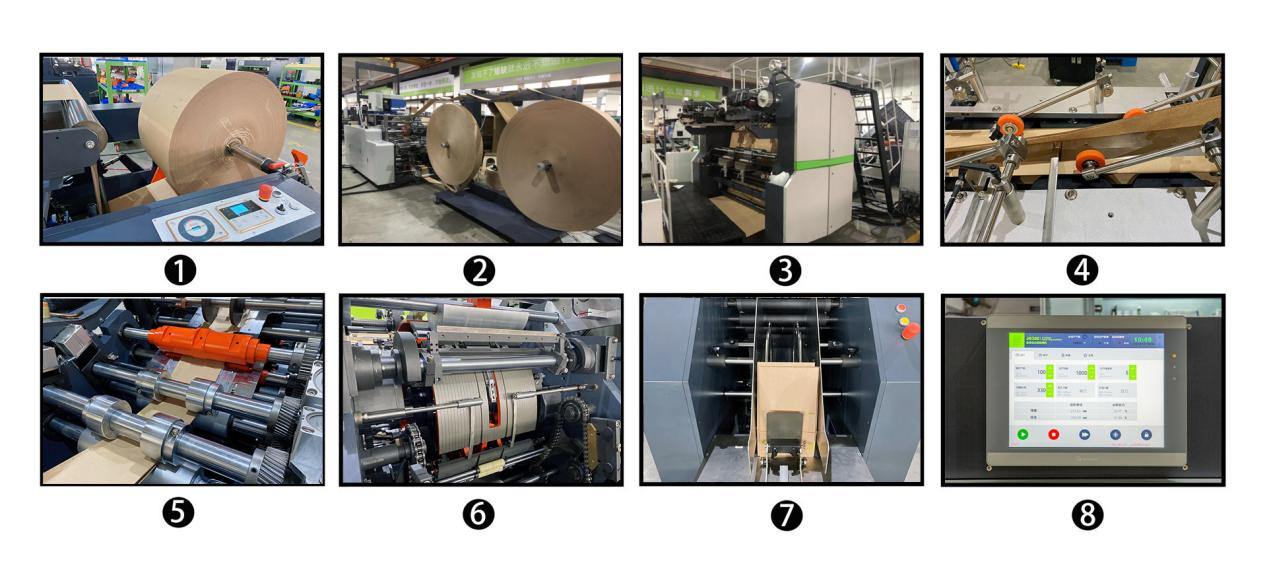

The advanced technology of the RKFD-550 Square bottom paper bag machine stands out as one of its most remarkable characteristics. With a touch screen interface, servo motor control system, and a photoelectric sensor for precise color tracking, this machine ensures consistent production of high-quality paper bags that meet all required standards.

Another notable aspect of the RKFD-550 Square bottom paper bag machine is its versatility. It has the capability to manufacture square bottom paper bags in various sizes, shapes, and styles, catering to the specific needs of individual users. Furthermore, this machine is capable of producing paper bags with or without handles, making it an ideal choice for businesses seeking flexible packaging options.

The RKFD-550 Square bottom paper bag machine is also highly efficient. It has a high production capacity and can produce up to 220 bags per minute, allowing businesses to meet their production targets in a timely and cost-effective manner. This high production capacity makes it an excellent choice for businesses that require large quantities of paper bags.

In terms of safety, the RKFD-550 Square bottom paper bag machine is designed to ensure maximum safety for its users. The machine is equipped with several safety features, including an emergency stop button, door interlocks, and overload protection. These features help to minimize the risk of accidents or damage, ensuring that the machine operates safely at all times.

The RKFD-550 Square bottom paper bag machine embodies innovation and efficiency in paper bag manufacturing. With High Speed production capabilities, it churns out top-quality square bottom paper bags, meeting diverse needs. Its Computerized interface and High precision mechanisms ensure consistent output, while Biodegradable materials uphold eco-friendly standards. This machine is the ultimate solution for businesses prioritizing quality, speed, and sustainability in packaging production.

To sum up, the RKFD-550 machine for square bottom paper bags is an incredibly advanced, flexible, and effective device that is ideal for companies in need of top-notch square bottom paper bags. Its cutting-edge technology, adaptability, impressive production capacity, and safety measures make it a superb choice for packaging industry businesses. By utilizing this machine, companies can enhance their efficiency, provide top-quality items to their customers, and uphold strict safety standards in their operations.