FAQ:

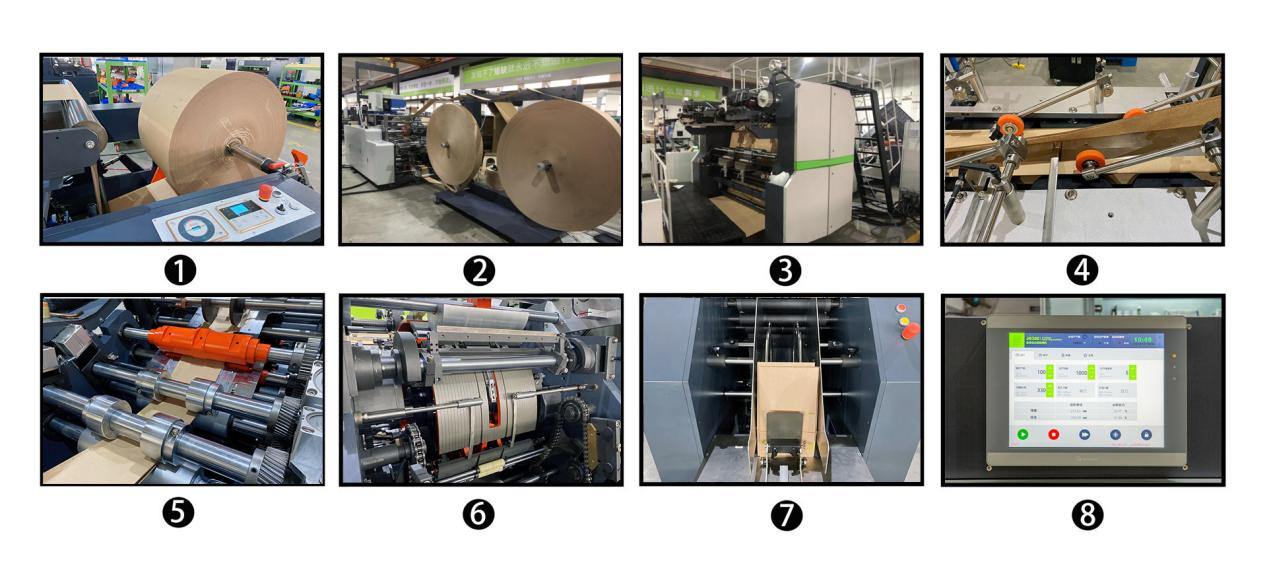

1.What is the maximum production speed of the RKFD-330 Square Bottom Paper Bag Machine?

The RKFD-330 Square Bottom Paper Bag Machine can produce up to 180 square bottom paper bags per minute, which equates to approximately 10,800 bags per hour.

2.What types of paper and materials can the RKFD-330 Square Bottom Paper Bag Machine handle?

The machine is versatile and can handle various types of paper, including kraft paper, coated paper, laminated paper, and non-woven fabric.

3.Can the RKFD-330 Square Bottom Paper Bag Machine produce bags in different sizes and designs?

Yes, the RKFD-330 is capable of producing paper bags in various sizes, thicknesses, and designs, offering customization options for different needs.

4.How does the RKFD-330 Square Bottom Paper Bag Machine ensure precise feeding, cutting, and gluing?

The machine is equipped with a photoelectric tracking system that ensures accurate feeding, cutting, and gluing of the paper bag components.

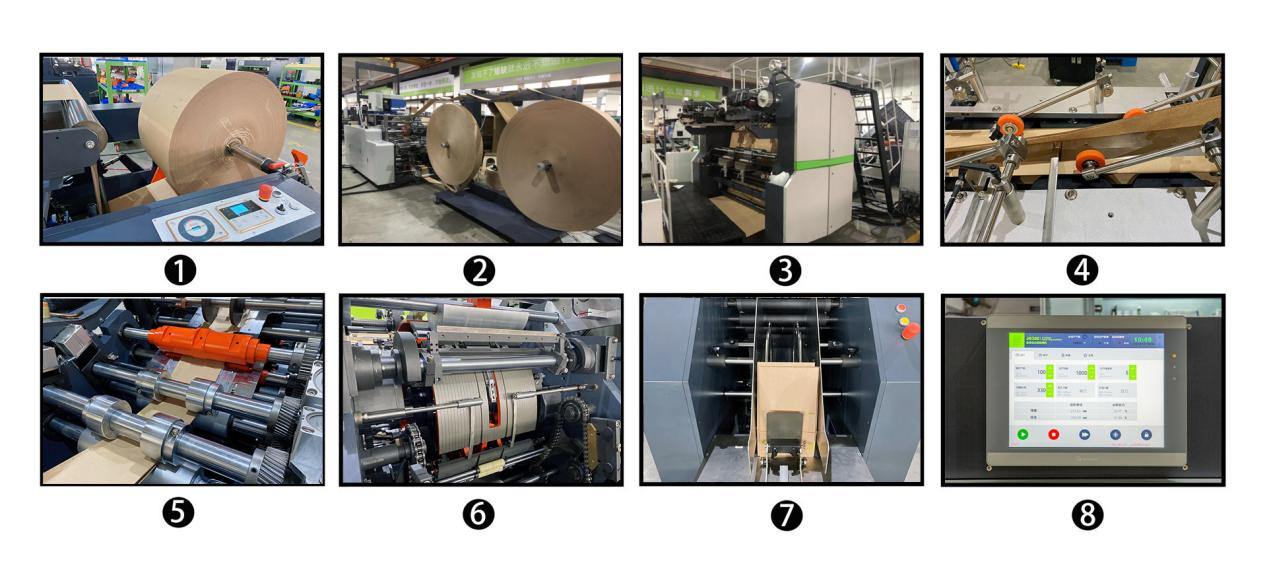

5.Is the RKFD-330 Square Bottom Paper Bag Machine user-friendly for new operators?

Yes, the machine features a user-friendly interface designed for ease of operation, making it accessible for both experienced and novice operators.

6.What is the benefit of the square bottom feature in the bags produced by the RKFD-330 Square Bottom Paper Bag Machine?

The square bottom allows the bags to stand upright on their own, providing a larger surface area for branding and product information.

7.How durable is the RKFD-330 Square Bottom Paper Bag Machine?

The RKFD-330 Square Bottom Paper Bag Machine is designed for durability and long-lasting performance, capable of withstanding the demands of heavy-use manufacturing environments.

8.What features help in maintaining high production efficiency with the RKFD-330 Square Bottom Paper Bag Machine?

Key features include an automatic gluing system, hydraulic sheet roller changing, and an automatic lubrication system to ensure smooth and efficient operation.

9.What support is available for operating and maintaining the RKFD-330 Square Bottom Paper Bag Machine?

The machine is supported by a comprehensive user manual, and the manufacturer offers customer support for troubleshooting and maintenance issues to ensure optimal performance.