The RKHF-330F Full automatic paper bag machine with flat handle is a highly advanced and efficient machine designed to produce high-quality paper bags with flat handles. This machine is fully automated, which means that it can produce paper bags continuously without the need for frequent human intervention. This makes it an ideal machine for large-scale production of paper bags.

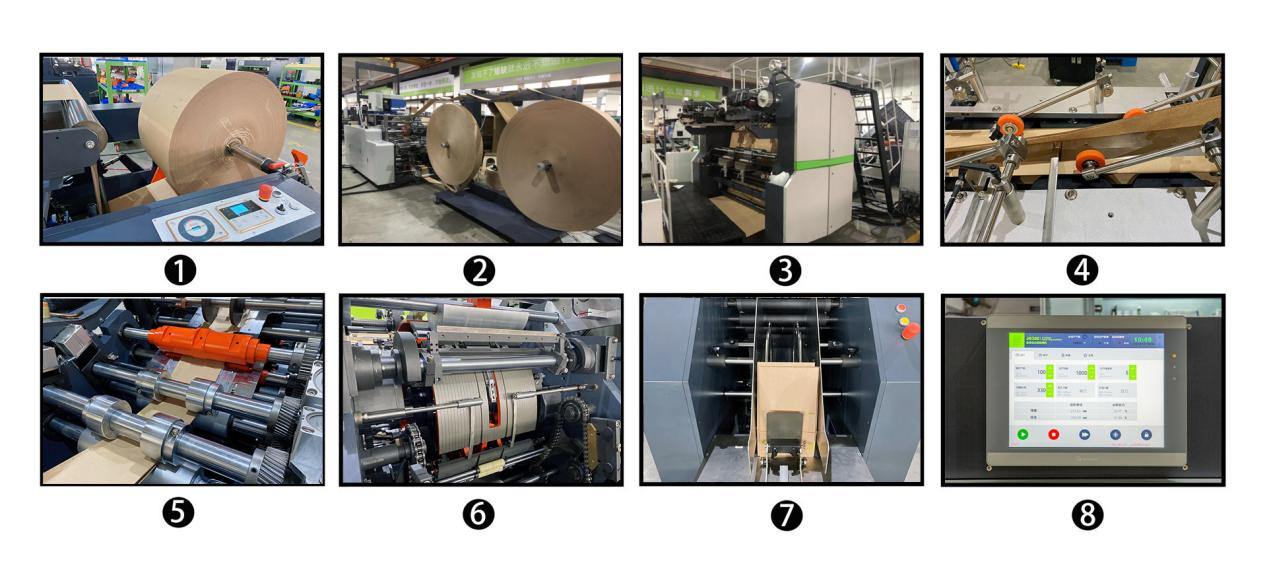

One of the most notable features of the RKHF-330F Full automatic paper bag machine with flat handle is its advanced technology. The machine is equipped with a touch screen interface, servo motor control system, and a photoelectric sensor for accurate color tracking. These features ensure that the machine produces consistent, high-quality paper bags that meet all requirements.

The versatility of the RKHF-330F Full automatic paper bag machine is another key feature. It can produce paper bags in various sizes, shapes, and styles, making it ideal for businesses with diverse packaging needs. Moreover, the machine can produce bags with flat handles, providing convenience and durability for customers.

Efficiency is also one of the strengths of the RKHF-330F Full automatic paper bag machine. With a production capacity of up to 220 bags per minute, businesses can meet high demands and maintain productivity. Additionally, the machine comes with a multi-functional electronic control system that monitors and regulates its operations, ensuring energy efficiency and cost-effectiveness.

The safety features of the RKHF-330F Full automatic paper bag machine are also noteworthy. The machine is equipped with an emergency stop button, door interlocks, and overload protection to minimize the risks of accidents or damages. These safety mechanisms ensure that the machine operates safely at all times and provides a secure working environment for operators and other personnel.

Additionally, the RKHF-330F stands out as a Biodegradable Full Automatic Paper Bag Machine, aligning with eco-friendly practices and sustainable production. This Computerized Full Automatic Paper Bag Machine offers precise control and customization, catering to various needs such as food bags, garment bags, and shopping bags. Its High Reliability Full Automatic Paper Bag Machine design ensures consistent performance and minimal downtime, while the Cost-effective Full Automatic Paper Bag Machine attribute provides an excellent return on investment. Enhance your business efficiency and sustainability by choosing the RKHF-330F, a machine that combines advanced technology with eco-friendly and reliable production capabilities.

In summary, the RKHF-330F Full automatic paper bag machine with flat handle is a highly advanced and versatile machine that provides businesses in the packaging industry with a reliable solution for producing high-quality paper bags with flat handles. Its advanced technology, versatility, production capacity, efficiency, and safety features make it an excellent investment for businesses seeking to meet high demands while maintaining quality and safety standards.