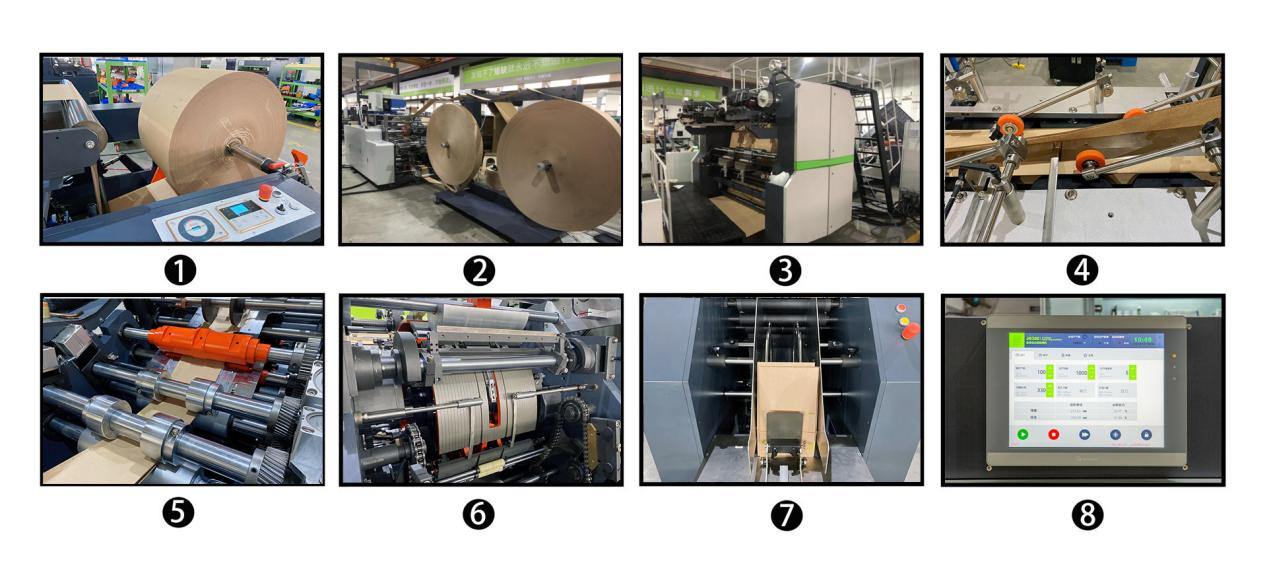

The advanced RKHF-330TF Fully automated paper bag machine with twisted and flat grip is a state-of-the-art device intended to enhance the efficiency of producing paper bags. This flexible machine enables manufacturers to cater to their customers' specific requirements by producing paper bags with either twisted or flat handles.

Fully automatic manufacturing process:

One of the outstanding characteristics of this device is its completely automated operation. Once the necessary configurations have been entered, the device will handle everything else - from inserting the paper to completing the final stages of bag production. This enables a high level of effectiveness and uniformity in the manufacturing process, while also reducing labor expenses.

User-friendly:

Another noteworthy feature of this device is its simplicity. The user-friendly interface and intuitive control panel make it effortless for operators to set up and monitor the device, even if they have no prior experience with similar machinery. Moreover, the device is designed with safety as a priority, incorporating various safety measures to prevent accidents or injuries.

High speed:

In terms of speed, the RKHF-330TF does not disappoint. It is capable of producing up to 220 bags per minute, making it an ideal choice for larger-scale operations. Additionally, its high-precision servo motor ensures that every bag produced is of consistent quality, with minimal waste.

Customizable options:

The RKHF-330TF is also highly customizable, with a range of settings and options that allow manufacturers to produce bags of different sizes and styles. This makes it a particularly useful tool for businesses that need to cater to a diverse range of customers and products.

Finally, the machine is built to last, with a sturdy construction and high-quality components that ensure it can withstand the rigors of constant use. This makes it a reliable investment for businesses looking to improve their paper bag manufacturing capabilities over the long term.

In general, the RKHF-330TF Full automatic paper bag machine with twisted and flat handle is a robust, effective, and adaptable device that can assist companies in enhancing their production procedures and satisfying their customers' needs. With its completely automated functioning, rapid speed, user-friendly nature, options for customization, and long-lasting construction, it is a superb option for businesses aiming to simplify their paper bag manufacturing.